-

English

English

-

Español

Español

-

Português

Português

-

русский

русский

-

français

français

-

日本語

日本語

-

Deutsch

Deutsch

-

Tiếng Việt

Tiếng Việt

-

Italiano

Italiano

-

Nederlands

Nederlands

-

ไทย

ไทย

-

Polski

Polski

-

한국어

한국어

-

Svenska

Svenska

-

magyar

magyar

-

Malay

Malay

-

Dansk

Dansk

-

Suomi

Suomi

-

عربى

عربى

-

norsk

norsk

-

اردو

اردو

-

čeština

čeština

-

Ελληνικά

Ελληνικά

-

Javanese

Javanese

-

български

български

-

ລາວ

ລາວ

-

Latine

Latine

-

Euskal

Euskal

-

Azərbaycan

Azərbaycan

-

slovenský

slovenský

-

Македонски

Македонски

-

Eesti Keel

Eesti Keel

-

Српски

Српски

-

Afrikaans

Afrikaans

-

עִברִית

עִברִית

-

icelandic

icelandic

-

Беларус

Беларус

-

Malti

Malti

-

lugha ya Kiswahili

lugha ya Kiswahili

-

አማርኛ

አማርኛ

-

Frysk

Frysk

-

ជនជាតិខ្មែរ

ជនជាតិខ្មែរ

-

ಕನ್ನಡ

ಕನ್ನಡ

-

Corsa

Corsa

-

Kurdî

Kurdî

-

മലയാളം

മലയാളം

-

Hmong

Hmong

-

Cebuano

Cebuano

-

Hawaiian

Hawaiian

-

Shinra

Shinra

Products

Zvigadzirwa Zvitsva

Yakapetwa Kaviri Yakazara Otomatiki Flip Suction Pulp Tableware Kugadzira Kucheka Kumucheto Integrated Machine

Yakapetwa Kaviri Yakazara Otomatiki Flip Suction Pulp Tableware Kugadzira Kucheka Kumucheto Integrated Machine Imwe-yekupedzisira Otomatiki Flip Suction Cup Lid Kugadzira Machine

Imwe-yekupedzisira Otomatiki Flip Suction Cup Lid Kugadzira Machine Semi-otomatiki Pulp Molding Tableware Kugadzira Machine

Semi-otomatiki Pulp Molding Tableware Kugadzira Machine Inobviswa Maviri-chiteshi Pulp Molding Machine

Inobviswa Maviri-chiteshi Pulp Molding Machine Inobviswa Imwe Chiteshi Pulp Molding Machine

Inobviswa Imwe Chiteshi Pulp Molding Machine

Otomatiki Flip Suction Pulp Molding Cup Lid yekugadzira muchina

Send Inquiry

Product Description

Machine

1. PRODUCT DETAILS of Fully Automatic Flip Suction Pulp Molding Cup Lid Forming Machine

1). Zvishandiso zvinoshandisika: pulp yakaumbwa kapu kavha, yepamusoro-yekupedzisira zvigadzirwa zvemagetsi zvigadzirwa, zvizorwa kurongedza, yepamusoro-yekupedzisira Baijiu kurongedza, yakakwirira kukosha-yakawedzera zvigadzirwa zvekurongedza zvemaoko.

2). Kugadzira nzira: reverse kuyamwa

3). Kurongeka saizi: 1100*800mm

4). Kupisa nzira: kupisa mafuta ekufambisa kana kupisa magetsi

5). Maximum boost pressure: 60t

6). Kukwirira kureba kwechigadzirwa chekugadzira: 150mm

7). Chigadzirwa chekufambisa modhi: yakawanda yakabatana robhoti kunze kwekufambisa mold

8). Kudzora maitiro: Siemens PLC

9). Kukwanisa kugadzira: tora makumi mapfumbamwe ekofi kapu inovhara semuenzaniso, ine imwe yakabuda makumi mana nemasere, huwandu hwezuva nezuva hwekugadzira hunosvika 130000 (5.5G), ingangoita 715kg

2. Equipment operation mode of Fully Automatic Flip Suction Pulp Molding Cup Lid Forming Machine

Robhoti nhanhatu axis multi joint robhoti inotora yakanyorova embryo yoiendesa kuruboshwe nekurudyi kunopisa kunodzvanya. Zvadaro, irobhoti rakabatana rakawanda rinotora chigadzirwa chakapedzwa kubva muchitsina chinopisa, chinochiisa pabhandi rekutakura uye otomatiki chichiendesa kunze kweguardrail. Pakupedzisira, chigadzirwa chakapedzwa chinounganidzwa nemaoko.

3. Equipment features of Fully Automatic Flip Suction Pulp Molding Cup Lid Forming Machine

1). Hunhu hwekugadzira nzira: iyo reverse suction nzira inogamuchirwa. Iwo mana pivot mapoinzi eiyo pulp bhokisi anosimuka uye anodonha synchronously. Kusveta kuri yunifomu, kusveta uye kukurumidza kwemvura kunokurumidza, pasi kunodyiswa ne pulp, uye chitarisiko chiri nyore. Kugadzirwa kwepasuru yebasa remhando yepamusoro kunogona kugadzira makavha emhando yepamusoro yekapu ine 0 dhizaini angle uye isingasviki 0 madhigirii (kureva inverted buckle)!

2). Iyo yepamusoro nepasi inofa nekutsikirira inopisa ine vacuum uye kuvhuvhuta kwemhepo mabasa

3). Iyo yese muchina inodzora sisitimu inodzorwa neMitsubishi PLC, ine yakakwira dhigirii yehumunhu hwekushanda interface, kuenzanisa nekugadzirisa dhizaini, nekuvandudza kugona kwekugadzira

4). Masilinda mana emafuta anoshandiswa kusimudza uye kudzikisa bhokisi repulp. Kusimudza nekudzikisira kwebhokisi remapepa kwakanyatso tsiga kuti ive nechokwadi chekukweva kweyunifomu, uye mwero wakakodzera wekugadzirwa kwemhando yepamusoro yezvigadzirwa zvepasuru yebasa wakakwira

5). Kaviri mativi ekugadzira muchina unogamuchirwa kutenderedza nekuyamwa pulp, ine hunyanzvi hwepamusoro uye yakagadzikana chimiro; Dhizaini yekusveta vacuum uye kuvhuvhuta pombi yekugadzira kufa ine musoro, uye kufuridza nekukweva mhedzisiro yakanaka

6). Iyo yekudziya ndiro inoiswa welded nemhando yepamusoro yealuminium, ine yakanyanya kupisa kupisa kunyatsoshanda. Imba yemhepo yakagadzirirwa kuenzanisa ndiro yekupisa, ndiro yepakati uye pasi pasi, kuitira kuti kupera kukurumidze uye chiyero chekufanirwa kwechigadzirwa chakakwirira.

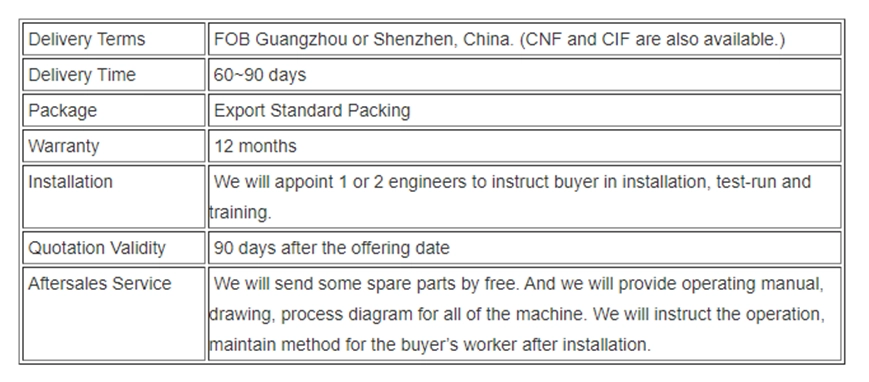

4. Business Terms of Fully Automatic Flip Suction Pulp Molding Cup Lid Forming Machine